Chotest Flash Measuring Machine VX9000 Series

Specifications

Details

Features

VX9000

Gantry-Structure Flash Measuring Machine

VX9000 series optical scanning imaging measuring machine is based on optical imaging measuring system, with high-precision motion mechanism and granite gantry-type base, to achieve the perfect combination of measurement accuracy, speed and stability; combined with high-precision image analysis algorithm, and integrated into the principle of flash measurement , Within the measurement range, the instrument can automatically locate the measurement object, match the template, measure the evaluation, and generate the report by placing the workpiece position, direction, and angle arbitrarily, so as to truly achieve fast and accurate measurement.

.png)

One-Key Precision Measurement

- In the measurement field of view, the product can be placed arbitrarily, and the measurement can be realized without a jig or fixture;

- In the measurement field of view, multiple products of the same specification can be placed arbitrarily, and each product can be measured at the same time;

- Support CAD drawing import, one-key automatic matching measurement.

- Automatic glass covering panel to avoid the movement of the test objects during measurement

Long-travel High-Speed Gantry Structure Platform

- Large measuring stroke (620x540mm~920x840mm), measuring speed 200mm/s, moving speed 500mm/s;

- High-precision granite base and beam, the overall structure is stable and reliable;

- The key motion mechanism is guided by high-precision linear guides, driven by AC servo direct-drive motor, and matched with a grating system ensure the high precision and high efficiency of the equipment.

.png)

Efficient Measurement

VX series is equipped with double telecentric optical lens with high depth of field and big field.

High depth of field: Without focusing multiple times, accurate measurement at entire of depth of field.

Big field: Measure all features of all objects within field in seconds

High-resolution Large-field Scanning Imaging System

- High-resolution line scan camera, detection accuracy can reach micron level;

- Double-sided telecentric lens with high telecentricity improves the measurement accuracy several times;

- Equipped with various program-controlled light sources such as bottom light, surface light and coaxial light to meet different measurement needs.

.png)

Applications

Standard stage is often used for PCB, flat metal, sheet parts, lithography patterns, etc.; customizable stage (jig) for machinery, electronics, molds, injection molding, hardware, precision stamping, connectors, connectors, Terminals, 3C, home appliances, tools and other fields.

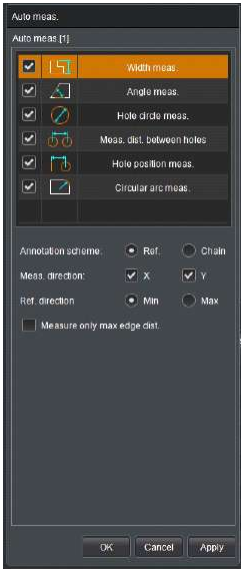

Measuring Software

VisionX is a professional visual measuring software developed by Chotest which is our own independent intellectual property rights. VisionX has friendly user interface, convenient operation, powerful and practical functions, support more than 80 kinds of extraction and analysis tools, including feature extraction tool, auxiliary tool, annotation tool and special application tool, etc. Also more function is customizable according to user`s requirements in order to improve the efficiency

.jpg)

Software Features

Geometric Tolerance: Straightness, Roundness, Concentricity, Symmetry, Positional Tolerance, Parallelism, Perpendicularity, Profile Tolerance, etc.

CNC Mode: Modify CNC program anytime, as well as adding or reducing features OK or NG is concluded according to tolerance in CNC program

Automatic: Only need to select the measuring features, after placing the workpiece, measuring results can be obtained quickly by one key

Coordinate System: Can create coordinate system by Point-line, Line-line, and translate & rotate coordinate system, as well as create multi-coordinate system

Special tools: Rounded corner, Contour, Thread, Slot, Perimeter, Pitch distance, Thickness, Chamfer, Spring, Gear, Sealing gasket, area, Pitch Angle, Boundary width

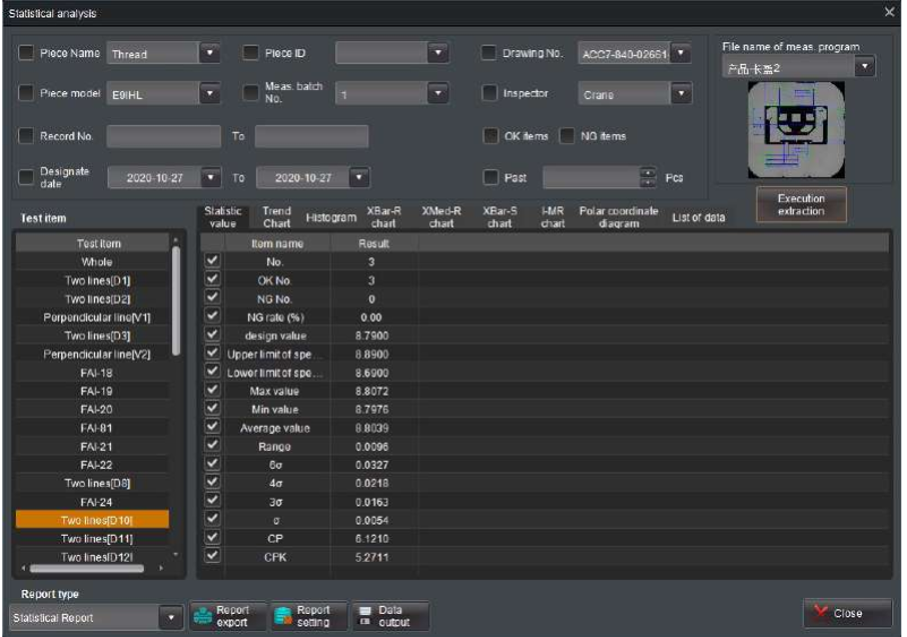

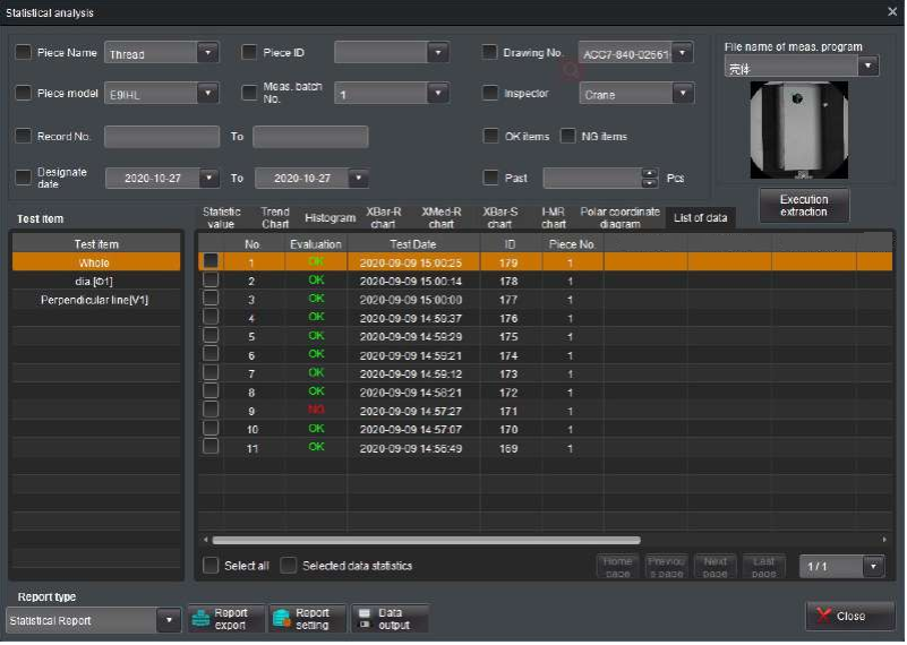

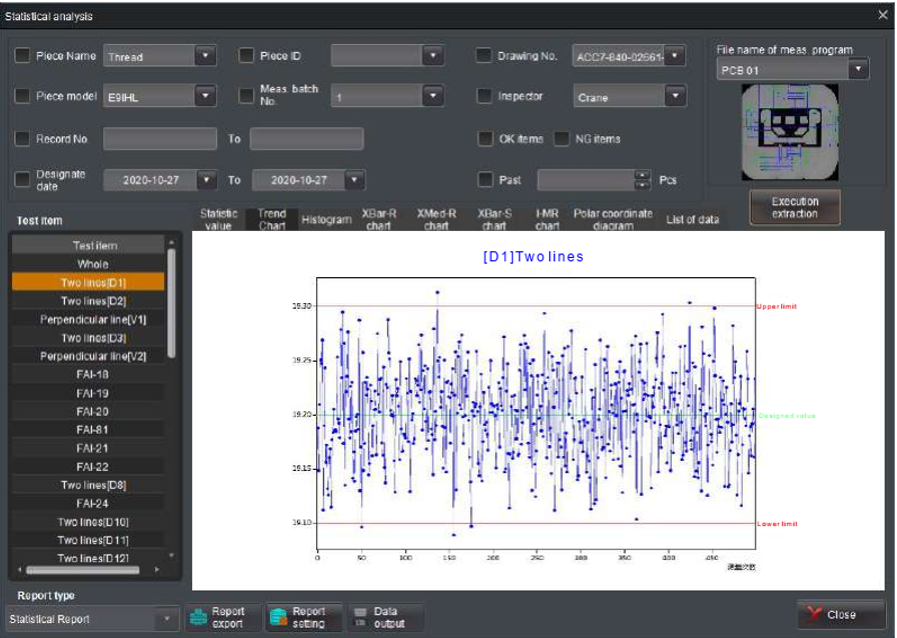

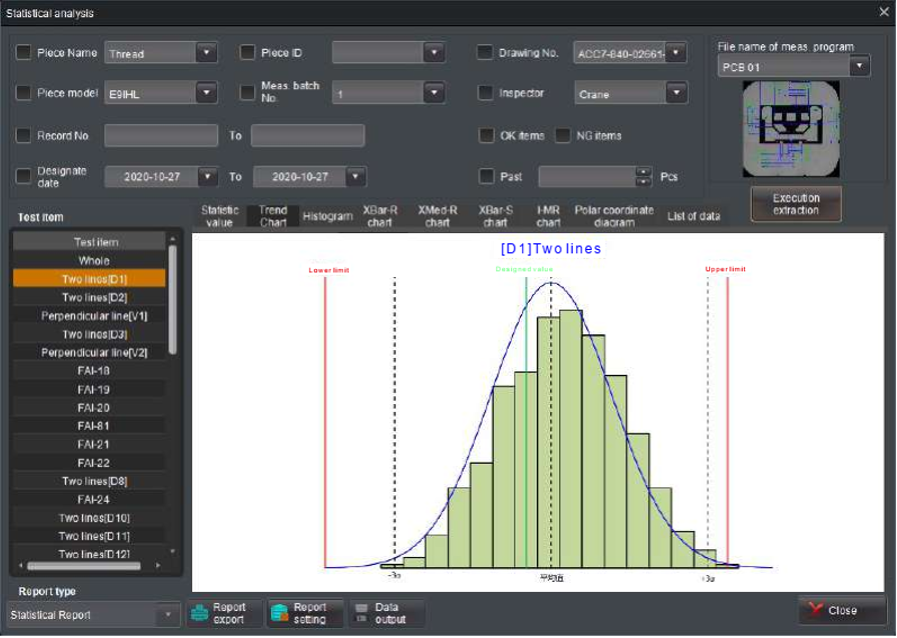

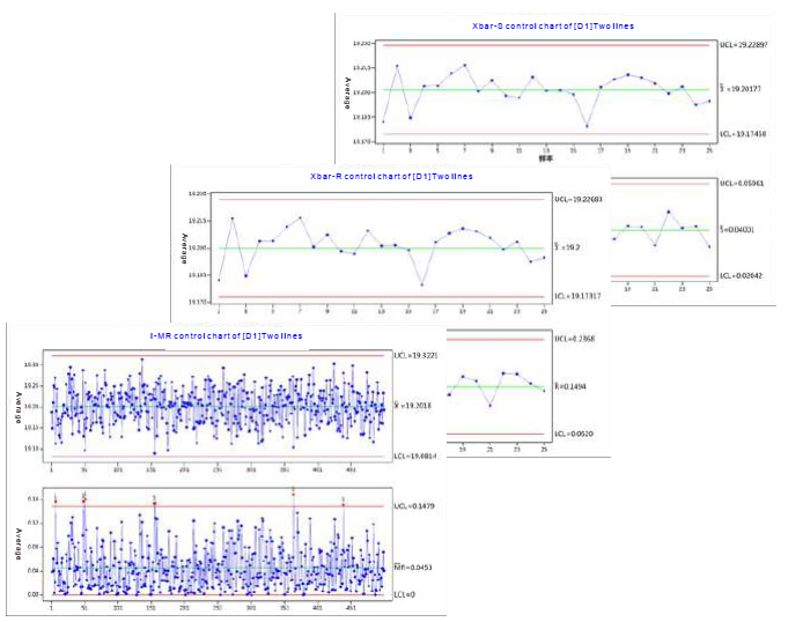

Statistical Analysis

The statistical analysis interface has the tabs of [Statistical Value], [Trend Chart], [Histogram] and [Data List]

Automatic recording and query

Measurement results and its main statistical information (e.g. average value, σ, 3σ, 6σ, Ca, Cp, Cpk etc) will be automatically recorded and saved. Operator could search records by different conditions.

Control Production Process and Improve Production Quality

The trend chart monitors the abnormalities of generating equipment and production process by regularly changing trend of measured values. Such as the monotonic and periodic changes of the measured values.

The histogram reflects the fluctuation and distribution of product quality, and transmits information about process quality, which can be used to judge and predict product quality and unqualified rate.

SPC analysis uses statistical methods to monitor product quality and production process trends through quality diagnostic analysis, which is the preventive part in production process and reduce

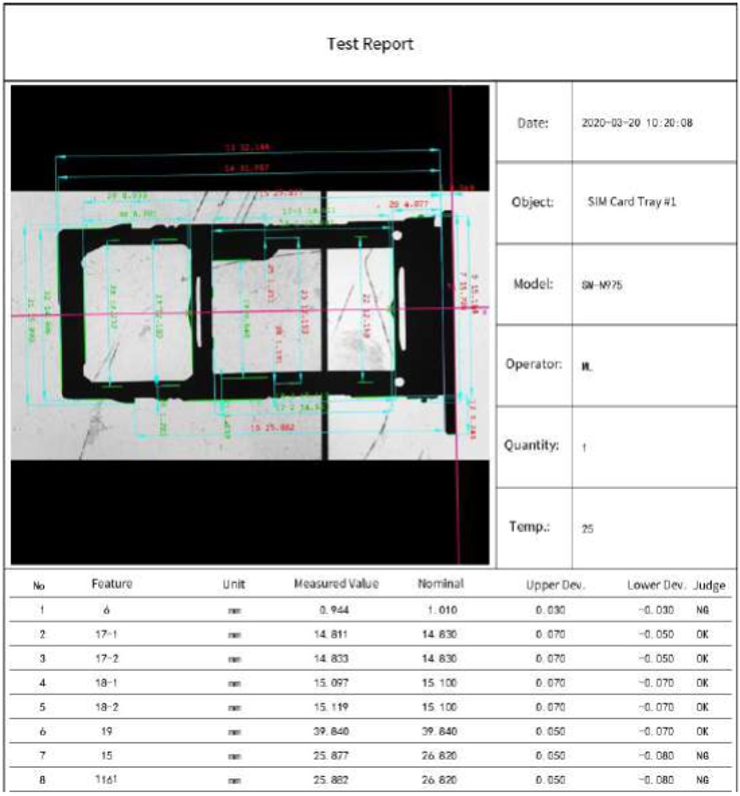

Generate Measurement Report Automatically by One Key

- Import and export Measurement records

- Different report format

- Support user-defined report template

- Able to saved as PDF, CSV files

- Quick export and print reports by one key

Specifications

Table 1

| Model No. | VX9600 Pro | VX9700 Pro | VX9800 Pro | VX9900 Pro | ||

| Measuring Range | X | 620mm | 720mm | 820mm | 920mm | |

| Y | 540mm | 640mm | 740mm | 840mm | ||

| Z (Thickness of Object) | 15mm | 15mm | 15mm | 15mm | ||

| Line Scan Accuracy | Accuracy *1 | ±(3.0+L/200) μm | ±(4.0+L/200) μm | |||

| Min Hole | Φ0.35mm | |||||

| Area Scan Camera with Zoom Lens *2 | Acceptance Lens | Motorized zoom lens (1 ~ 12.5X) | ||||

| Accuracy *1 | ±(3.0+L/200) μm | |||||

| Accuracy of Single F.O.V *1 | ± 2.0μm | |||||

| Min Hole | Φ40mm | |||||

|

Height Measurement (Optical Probe) (Optional) |

Z Non-move | Range | ±3.5mm | |||

| Accuracy | ± 2.0μm | |||||

| Z Move | Range | 15mm | ||||

| Accuracy | ±(6.0+L/100) μm | |||||

| Max Hole/Depth Ratio(h/Φ) | 1.5 | |||||

| Dia. of Beam | Φ38μm | |||||

| Loading Capacity | 10kg | |||||

| Max Scanning Speed | 200mm/s | |||||

| Scanning Width | 89mm | |||||

| Max Moving Speed | 500mm/s | |||||

| Double Imaging System | [1] High-resolution line scan camera + Double-sided telecentric lens [2] High-resolution area scan camera + Motorized zoom lens |

|||||

| Covering Panel | Automatic glass covering panel | |||||

| Temp. Sensor | Temp. Compensation Function | |||||

| Joystick | Portable Joystick | |||||

| Lighting | Surface Light | RGB LED surface light + RGB LED coaxial light | ||||

| Bottom Light | Bar-shaped LED light | |||||

| Software | VisionXS Pro | |||||

| Air Pressure | 0.6MPa; 20L/min | |||||

| Power Supply | AC210~230V,50/60Hz, 25A 3.5KW | |||||

| Working Environment | Temp.20℃±1℃/hour, Humidity 30~80%, Vibration<0.002g, Less than 10Hz | |||||

| Size (mm) | 1825 x 1357 x 1865 | 1925 x 1457 x 1865 | 2025 x 1557 x 1865 | 2125 x 1657 x 1865 | ||

| Weight | 2500KG | |||||

Note:

*1 In the focus position, the environment temperature is 20℃±1.0℃

*2 Measuring range by the area scan camera is slightly smaller than that by the line scan camera.

Table 2

| Model No. | VX9600 | VX9700 | VX9800 | VX9900 | ||

| Measuring Range | X | 620mm | 720mm | 820mm | 920mm | |

| Y | 540mm | 640mm | 740mm | 840mm | ||

| Z (Thickness of Object) | 15mm | 15mm | 15mm | 15mm | ||

| Accuracy *1 | ±(3.0+L/200) μm | ±(4.0+L/200) μm | ||||

| Min Hole | Φ0.35mm | |||||

|

Height Measurement (Optical Probe) (Optional) |

Z Non-move | Range | ±3.5mm | |||

| Accuracy | ± 2.0μm | |||||

| Z Move | Range | 15mm | ||||

| Accuracy | ±(6.0+L/100) μm | |||||

| Max Hole/Depth Ratio(h/Φ) | 1.5 | |||||

| Dia. of Beam | Φ38μm | |||||

| Loading Capacity | 10kg | |||||

| Max Scanning Speed | 200mm/s | |||||

| Scanning Width | 89mm | |||||

| Max Moving Speed | 500mm/s | |||||

| Double Imaging System | High-resolution line scan camera + Double-sided telecentric lens | |||||

| Covering Panel | Automatic glass covering panel | |||||

| Temp. Sensor | Temp. Compensation Function | |||||

| Joystick | Portable Joystick | |||||

| Lighting | Surface Light | RGB LED surface light + RGB LED coaxial light | ||||

| Bottom Light | Bar-shaped LED light | |||||

| Software | VisionXS Pro | |||||

| Air Pressure | 0.6MPa; 20L/min | |||||

| Power Supply | AC210~230V,50/60Hz, 25A 3.5KW | |||||

| Working Environment | Temp.20℃±1℃/hour, Humidity 30~80%, Vibration<0.002g, Less than 10Hz | |||||

| Size (mm) | 1825 x 1357 x 1865 | 1925 x 1457 x 1865 | 2025 x 1557 x 1865 | 2125 x 1657 x 1865 | ||

| Weight | 2500KG | |||||

Note:

*1 In the focus position, the environment temperature is 20℃±1.0℃

Configurations

| Host Machine | 1 pc | Standard |

| High Resolution Line Camera | 1 pc | Standard |

| Double Sided Telecentric Lens | 1 pc | Standard |

| Bar-shaped LED Bottom Light | 1 pc | Standard |

| LED Surface Light | 1 pc | Standard |

| LED Coaxial Light | 1 pc | Standard |

| Automatic Glass Covering Panel | 1 pc | Standard |

| 24″ Monitor | 1 pc | Standard |

| Desktop Computer | 1 pc | Standard |

| Portable Joystick | 1 pc | Standard |

| VisionXS Pro Software | 1 pc | Standard |

| CAD Importing Software Module | 1 pc | Standard |

| Area Scan Camera with Zoom Lens | 1 pc | Standard for VX9000 Pro series |

| User Manual | 1 pc | Standard |

| Data exchanging software module (TCP transmission, Excel transmission in real time) |

1 pc | Optional |

| Q-DAS software module | 1 pc | Optional |

| Optical probe for height measurement | 1 pc | Optional |

| Intelligent electric meter | 1 pc | Optional |

| Anti-vibration system | 1 pc | Optional |

View more about Chotest Flash Measuring Machine VX9000 Series on main site