Matsuzawa Micro Vickers Hardness Tester (MMT Series)

Specifications

Details

Manual Micro Vickers Hardness Tester MMT series for Micro Vickers Hardness Testing by MSP Metrology (M) Sdn Bhd from Matsuzawa Japan

Features

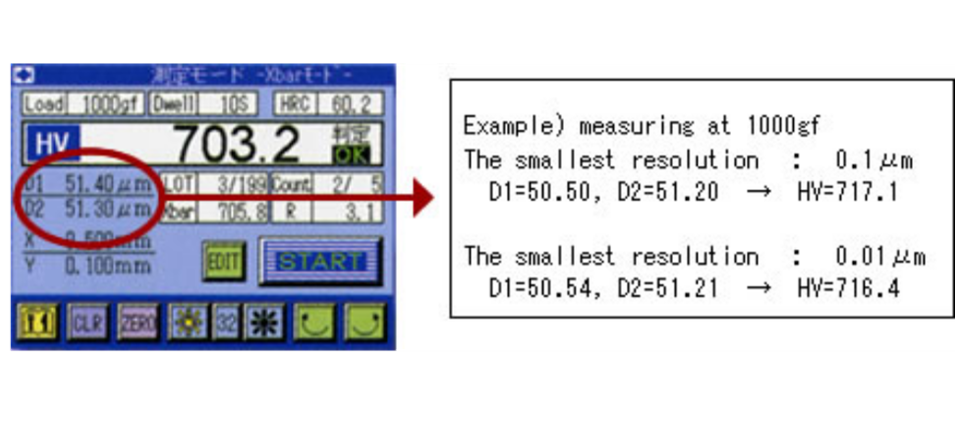

0.01µm MEASURING

Realize 0.01μm measurement at general magnification of 200x – 1,000x.

Possible to measure with accurate numerical value about a small indentation.

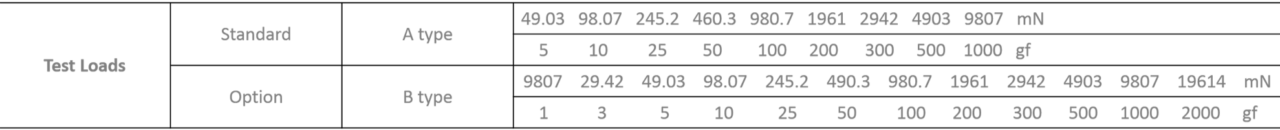

WIDE TEST LOAD RANGE

By wide test load range of 9 level(type A) and 12 levels(type B), testing of 1-2000gf can be done.

TESTING AREA OF INDUSTRY MAXIMUM CLASS

By a new design, testing range of specimen height 120mm and specimen depth 160mm was secured

.png)

THE UNIQUE TURRETT

The turret which mounted with two indenter and four objective lens following conventional stable loading mechanism.

COLOR LCD TOUCH PANEL

Visibility and operativity improve by color LCD. Equipped with the assist function that can identify the most suitable measurement condition

LINE UP IN LCD MODEL

Clear specimen surface image magnified on LCD monitor is displayed. Because the measurement knob is placed in the measurement panel, you can significantly reduce the fatigue of working long hours

Specifications

| ITEM | MMT-X7 | MMT-X3 | MMT-X1 | |

| Test Force | Standard Type A | 49.03 98.07 245.2 490.3 980.7 1961 2942 4903 9807 mN | ||

| 5 10 25 50 100 200 300 500 1000 kgf | ||||

| Standard Type B | 9.807 29.42 49.03 98.07 245.2 490.3 980.7 1961 2942 4903 9807 19614 mN | |||

| 1 3 5 10 25 50 100 200 300 500 1000 2000 kgf | ||||

| Loading Mechanism | Automatic Loading and Releasing Method | |||

| Indenter Approach Speed | 50µm/sec | |||

| Dwell Time | 5 ~ 99 sec | 5 ~ 30 sec | ||

| Indenter | Standard: 1 (HV), Option: 2 (HV, HK) | |||

| Objective Lens | Standard: 2 (40x, 10x ∴in case of AMT-PS/FS series: 40x, 50x), Option: Max. 4 (5x ~ 100x) | |||

| Eyepiece Lens | Standard 10x, Option 15x | |||

| Total Magnification | Standard (400x, 100x) Corresponding 50x ~ 1000x | |||

| Measuring Microscope (total 400x) | Max. Measuring Length | 250µm | ||

| Min. Scale | 0.01µm (200x~ 1000x) | 0.5µm | ||

| Min. Measuring Unit | 0.01µm (200x ~ 1000x) | 0.1µm | ||

| Measuring Type | Electronic | Mechanical | ||

| Data Output | Centronics (Dot printer output) | – | ||

| RS232C (Output for PC) Possible to change to printer output | ||||

| Light Source | LED Light Source | |||

| Turret | Auto | Manual | ||

| LCD Touch Panel | Color LCD touch panel | – | ||

| Testing Mode | 6 kinds of HV, HK, HBS, KC, Xbar, Cylindrical Correction | – | ||

| Data Memory | 999 data memory | |||

| Hardness Conversion | Possible in compliance with SAE (J-417B), ASTM (E-140) | |||

| OK/NG Criteria | Judging to the result by setting Max. and Min. | – | ||

| Statistical Calculation | Max. value, Min. value, dispersion (R), mean value, converted value | – | ||

| Accuracy | According to JIS B7725 and ASTM E-384 | |||

| Max. Specimen Height | 120mm | |||

| Max. Specimen Depth | 160mm | |||

| Dimensions and Weight | Main body only W250 x D520 x H530mm, 35kg | |||

| Photo Booth | Can be installed in the body tube in the upper part of the main body at any time | |||

| Power Supply | Single Phase AC100 ~ 240V 50/60Hz available for export models | |||

Optional Accessories

Touch Probe

After the equipment is installed with probe, it can be used to measure the following parameters:

- Height, width, length

- The angle between the two sides

- Vertical angle of cone

- Diameter of cylinder

- Chamfer

- Straightness, flatness, roundness, cylindricity

- Verticality, parallelism, inclination, and so on.

Coaxial Light Source with Different Effect

Joystick

Part Accessories

4-ring 8-division LED Surface Illumination

LED Parallel Contour Illumination

Zoom Lens

Video Capture Card

CCD Camera

Calibration Glass Stage

Data Integration Box

Software Dongle

Workbench

Computer System

Linear Scale

AV Cable

View more about Matsuzawa Micro Vickers Hardness Tester (MMT Series) on main site