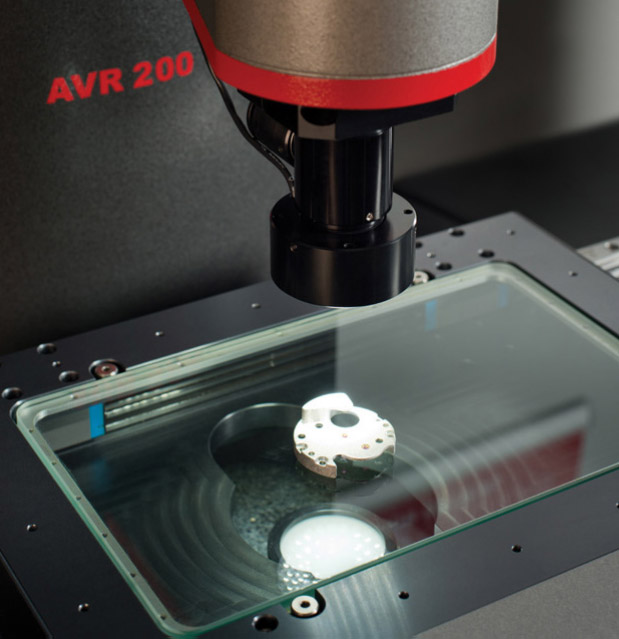

Starrett Auto Vision Measuring System (AVR Series)

Specifications

Details

Features

Two models available

MVR series features two models available which are MVR200 (X-Y travel of 200mm x 100mm) and MVR300 (X-Y travel of 300mm x 200mm)

High level of resolution and accurate field of view

With the video Edge Detection (VED) functions, all edges of the specimen can be easily detached. The Field-of-View (FOV) measurements are integrated with the stage motion.

Special 3 LED lights for perfect illumination

AVR series features 3 LED light function when user selected the 12:1 zoom optics. They included the colimated LED sub-stage illumination, ring light LED surface illumination and coaxial light illumination.

Fully motorized CNC machine

Full CNC X-Y-Z positioning or motorized manual positioning using a pendant with joystick and trackball

Integrated with powerful metlogix control system software

AVR series are suit up with the powerful control system software from MetLogix, M3. The M3 software has an advance functions like DXF importing and CAD comparison, auto edge detection, and works with active part views and live video feeds.

Specifications

- Z travel: 8″ (200mm) with 2.0x auxiliary lens

- Full CNC X-Y-Z positioning or motorized manual positioning using a pendant with joystick and trackball

- Windows® 7 Professional operating system

- MetLogix™ M3 CNC metrology software

- Video Edge Detection (VED)

- Field-of-view (FOV) measurements integrated with stage motion

- Renishaw scales for 0.00002″ (0.1μm) of X, Y and Z axis

- Color digital video camera

- Collimated LED sub-stage illumination

- Ring light LED surface illumination

- Granite base

Optional

- Dedicated 6.5:1 or 12:1 zoom optics

- Quick-change bayonet lens mount for telecentric optics

- Bayonet mountable 0.30x, 0.50x, 0.80x, 1,0x, 2.0x, 4.0x telecentric optics and 6.5:1 manual zoom lens

- 0.5x, 1.5, and 2.0x auxiliary lenses for zoom optics

- Renishaw Touch Probe kit

- Quadrant LED surface illumination for zoom optics

- DXF/FOV option pack for automatic comparison to CAD design

- Modular system workstation

- Calibration Standard

- Part fixtures and work holding devices

Comparison between AVR200 & AVR300

| Series/Features | AVR200 | AVR300 |

| System Type | Bench Top | Bench Top |

| Part View Orientation | Vertical | Vertical |

| X-Y-Z Travel | 200 x 100 x 200 | 300 x 200 x 200 |

| Z-axis Measuring | Standard | Standard |

| CNC | Standard | Standard |

| X-Y Accuracy (μm) | E2 = 1.9μm + 5L/1000 | E2 = 1.9μm + 5L/1000 |

| Z Accuracy (μm) | E1 = 2.5μm + 5L/1000 | E1 = 2.5μm + 5L/1000 |

| Scale Resolution | 0.1μm | 0.1μm |

| Base | Granite | Granite |

| Control System/Software | M3 Metlogix | M3 Metlogix |

| Display | 21″ Touchscreen PC | 21″ Touchscreen PC |

| Zoom Optics – Standard | 6.5:1 | 6.5:1 |

| Zoom Optics – Optional | 12:1 | 12:1 |

| Digital Video Camera |

1MP Color Standard 2MP with Telecentric Lens |

1MP Color Standard 2MP with Telecentric Lens |

| Surface Ring Illumination | LED | LED |

| Transmitted Illumination | LED | LED |

| Coaxial Illumination | Optional LED | Optional LED |

| Darkfield Quadrant Illumination (Optinal LED only) | Optional LED | Optional LED |

| Brightfield Quadrant Illumination (Optional LED only) | Optional LED | Optional LED |

| Auxiliary Lens (Optional) | 0.5X, 1.5X, 2.0X | 0.5X, 1.5X, 2.0X |

| Telecentric Lens (Required on FOV &HDV) | .3X, .5X, .8X, 1.0X, 2.0X, 4.0X | .3X, .5X, .8X, 1.0X, 2.0X, 4.0X |

| Net Weight |

145lbs 66kg |

225lbs 102kg |

| Shipping Weight |

250lbs 115kg |

300lbs 135kg |

| Dimension (mm) | 863 x 520 x 685 | 860 x 740 x 890 |

View more about Starrett Auto Vision Measuring System (AVR Series) on main site